Product Details

Product Introduction

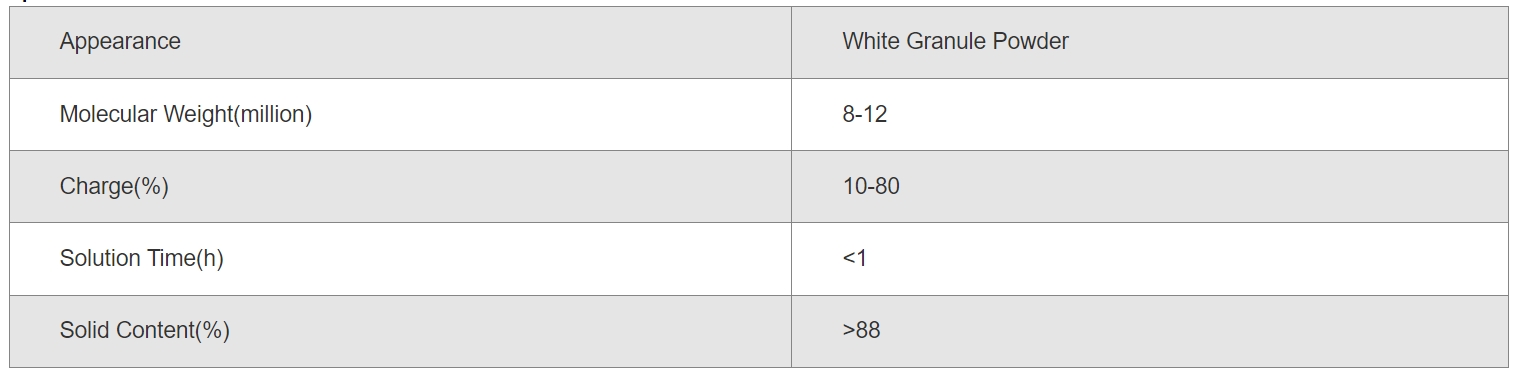

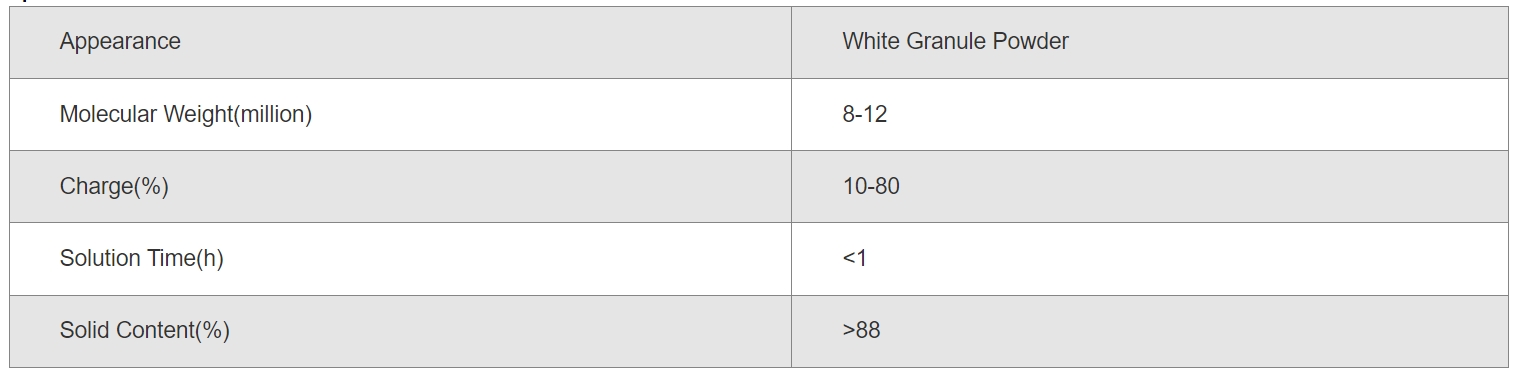

Wet and dry reinforcing agents, namely polyacrylamide (PAM), are important additives widely used in various industries, and their types include anionic, cationic, nonionic and zwitterionic. The molecular formula of this product is C3H5NO, and its CAS number is 9003-05-8. Our wet and dry enhancers have passed multiple certifications such as ISO, S9001, SO14001 and OHSAS to ensure their quality and safety. The product is a white granular powder with high molecular weight (8 million to 12 million) and high solid content (more than 88%). Its main advantage is that as a fixing agent at the wet end of the paper machine, it performs well when the dosage is small but the effect is significant. It can be used in acidic and neutral sizing papermaking systems. Cationic PAM significantly improves the fixation rate of fillers and fine materials during the papermaking process through bridge flocculation, accelerates the drainage of paper materials in the paper machine mesh, and increases cationization in the particle system to form large flocs. Improve the forming effect and quality of paper.

Advantages and features

1. The products have passed multiple certifications such as ISO, S9001, SO14001 and OHSAS, and their quality and safety are guaranteed. 2. The molecular weight is as high as 8 million to 12 million, and the solid content is greater than 88%, providing excellent reinforcing effects. 3. It has a bridging flocculation effect, which significantly improves the fixation rate of fillers and fine materials during the papermaking process. 4. The dissolution time is less than 1 hour, the operation is fast and efficient, and it has wide applicability. 5. Cationic PAM enhances the drainage effect and forming quality of paper, and improves the overall quality of paper.

Application Scenario

1. Applicable to various industrial wastewater treatment and municipal sewage treatment. 2. Widely used in oil fields, metallurgy, coal and sand washing industries. 3. Applicable to acidic and neutral sizing papermaking systems in the papermaking industry.