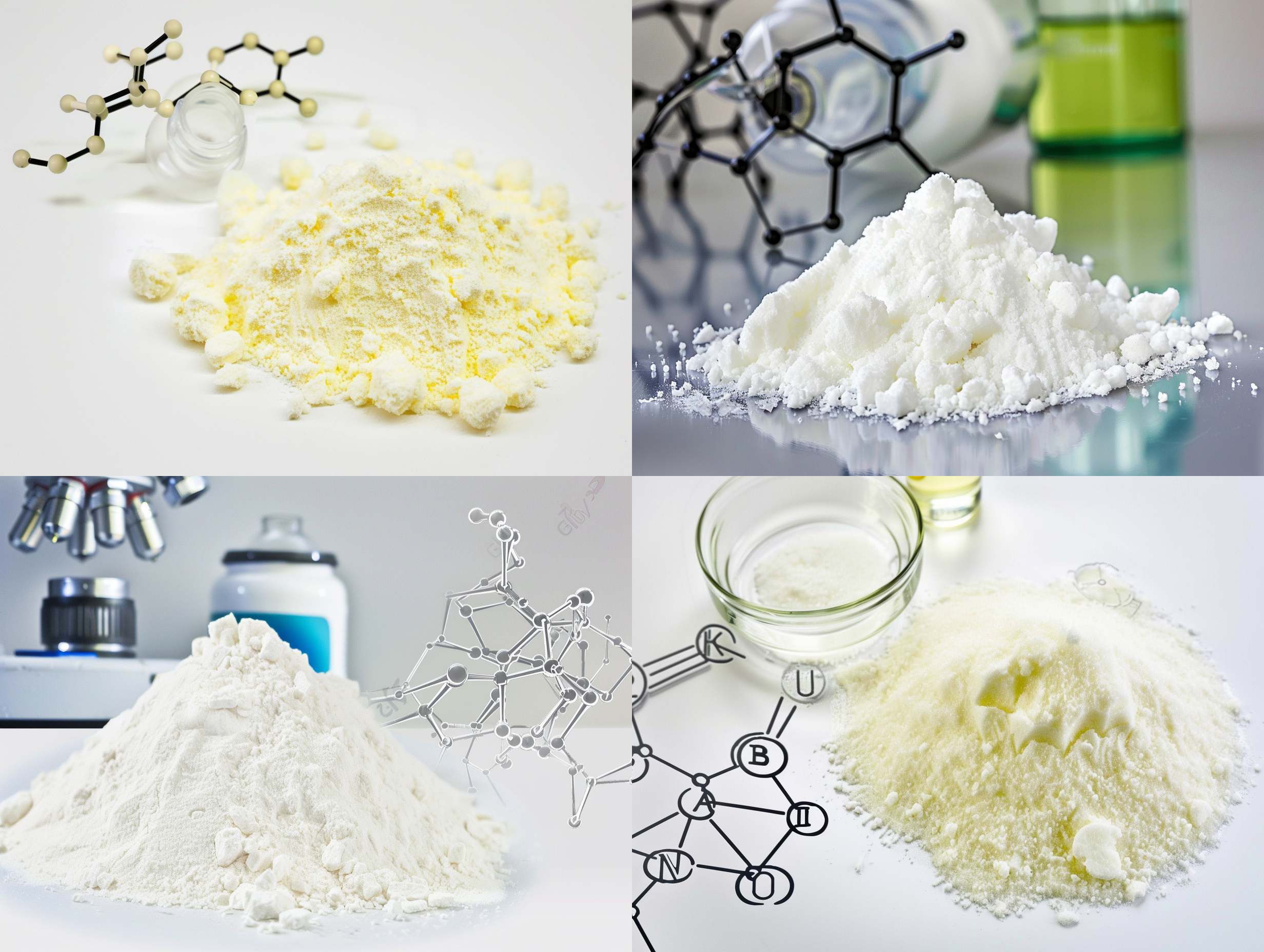

As a leader in the rubber manufacturing industry, I understand the essential role rubber accelerators play in improving product performance. These chemical additives not only enhance the durability of rubber products but also optimize their overall quality.

Rubber accelerators facilitate the vulcanization process, allowing for stronger cross-linking in rubber compounds. This process significantly improves the performance of rubber products in various applications.

2.jpg)

In my experience, using specific types of accelerators, such as MBT and DCBS, can lead to quantifiable improvements in product performance metrics. For example, independent studies have shown that the use of DCBS can increase tensile strength by over 25% in certain rubber formulations.

Additionally, as we work towards sustainable solutions, the choice of rubber accelerators plays a pivotal part in reducing environmental impact while maintaining high manufacturing standards. It's critical to stay informed about the latest advancements in these chemical additives, ensuring that our products remain competitive in an evolving market.

In conclusion, by harnessing the full potential of rubber accelerators, we not only enhance product quality but also drive innovation and efficiency in rubber manufacturing. Let's continue to explore and invest in these critical additives for sustained growth and success.