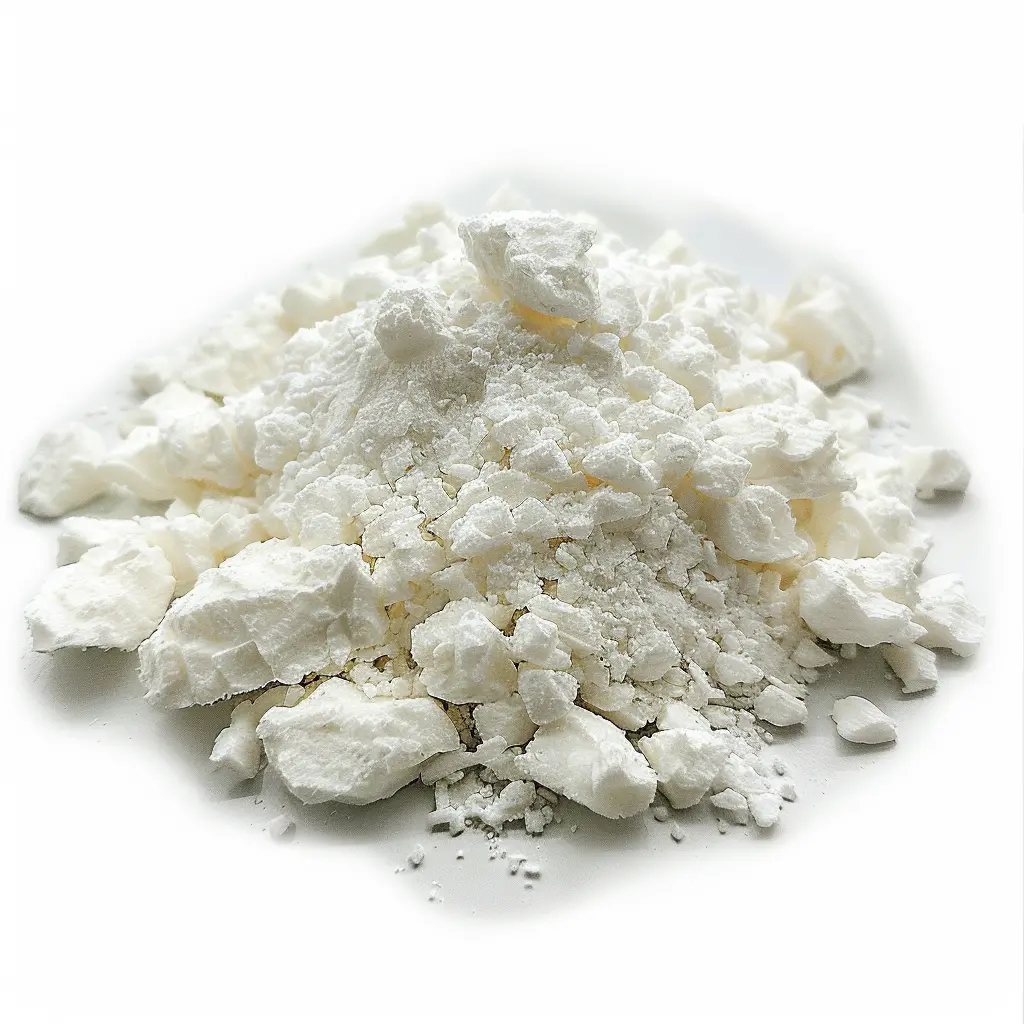

In the realm of rubber production, selecting the right curing accelerators is critical to ensuring product quality and performance. The sulfur cure accelerator DCBS(DZ) stands out with its exceptional properties and versatile applications. It is particularly advantageous in the manufacturing of crucial rubber products, including radial tires, shock absorbers, and rubber belts.

DCBS(DZ) is known for its excellent dispersion characteristics, which leads to uniform vulcanization and enhanced mechanical properties of the final rubber products. Its optimal performance in terms of processing temperatures makes it suitable for a wide range of production environments. Moreover, DCBS(DZ) boasts a favorable aging resistance profile, contributing to the longevity and durability of the end products.

The versatility of DCBS(DZ) facilitates its use in various commercial applications. In the automotive industry, it plays a pivotal role in the production of radial tires and shock absorbers, where high-performance standards are requisite. Additionally, its application in manufacturing rubber belts illustrates its adaptability across different rubber product categories.

Utilizing DCBS(DZ) in rubber production not only enhances the quality of the products but also optimizes the manufacturing process. Its effectiveness reduces production times and improves cost efficiency, making it a favorite choice among manufacturers aiming for competitive advantage. Furthermore, the improved physical properties of rubber products result in greater customer satisfaction and reduced product failure rates.

In conclusion, the sulfur cure accelerator DCBS(DZ) is a key component in the rubber industry, contributing to the development of high-quality products while enhancing production efficiency. Its unique properties and wide-ranging applications make it an indispensable tool for manufacturers seeking to excel in a competitive market.