As an important part of the synthetic rubber industry, plasticizers play a pivotal role in improving rubber properties. By optimizing its application, we can effectively improve the market competitiveness of our products to meet the needs of different industries.

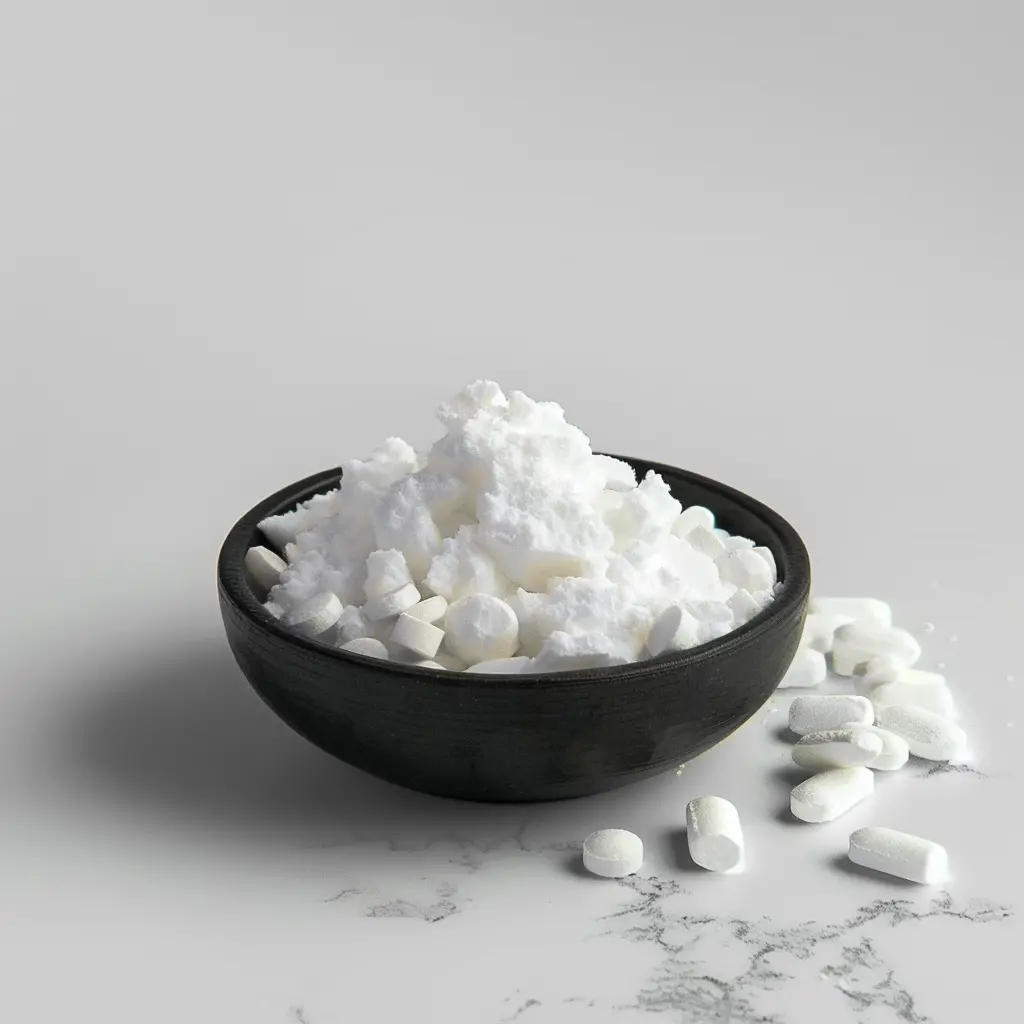

Plasticizers mainly improve the flexibility and processing properties of rubber by reducing the interaction between polymers. Common plasticizers include esters and alcohols, which can significantly improve the physical properties of rubber so that it can maintain excellent performance under various climatic and environmental conditions.

Plasticizers are widely used in industries such as automotive, electronics and construction. In the automotive industry, they help reduce body weight and improve fuel efficiency; in the electronics industry, plasticizers improve the durability and insulation of products; and in the construction industry, they increase the durability and corrosion resistance of materials. sex.

By rationally selecting and using plasticizers, companies can not only improve product quality, but also effectively reduce production costs and enhance market competitiveness. This process is particularly important for large manufacturing companies. Reasonable plasticizer configuration can reduce production costs and increase profit margins while ensuring product quality.

Taken together, the application of plasticizers in synthetic rubber is extremely extensive and important. Not only do they improve rubber performance, they also provide the industry with more efficient and reliable product solutions. As a decision-maker, I will continue to pay attention to the market dynamics and innovative applications of plasticizers to ensure that our products remain at the forefront of the industry.