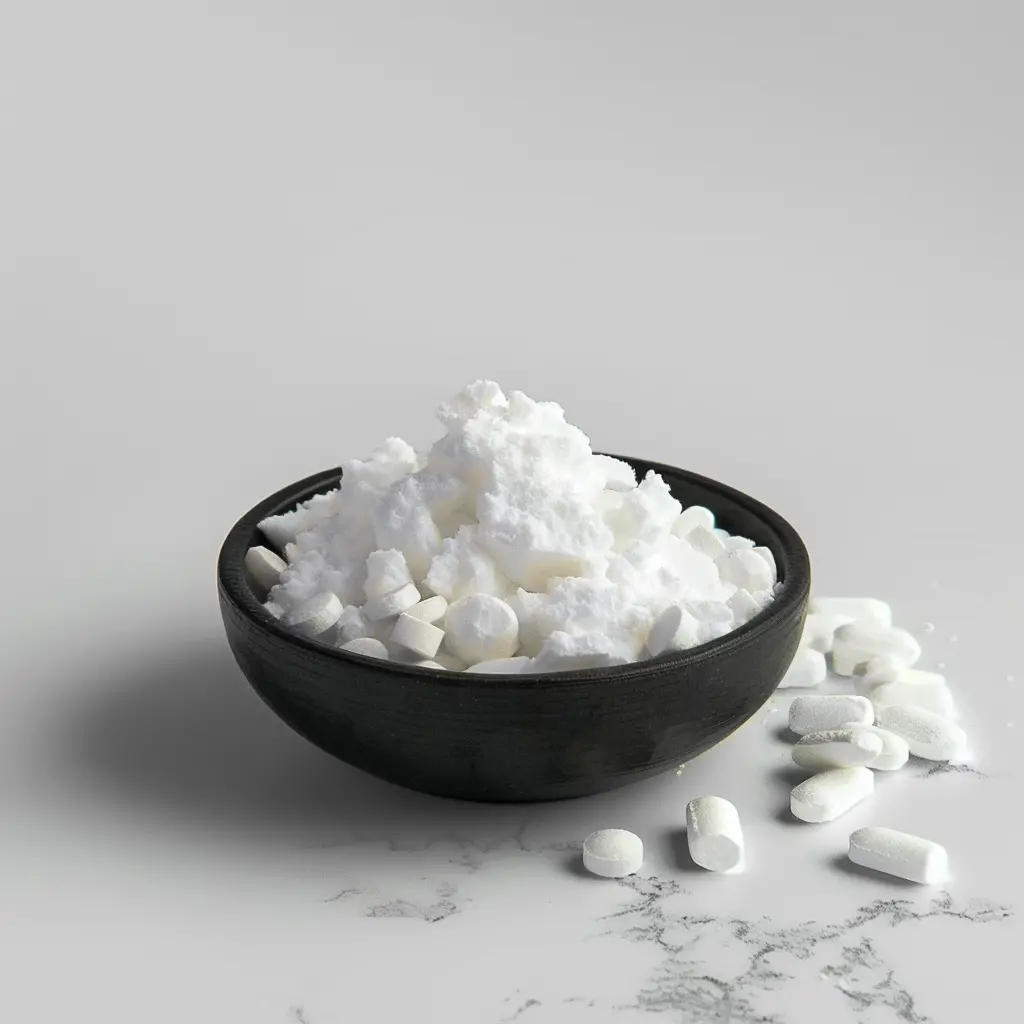

In the rubber industry, the selection of rubber vulcanizer is critical to the performance of the final product. As an efficient vulcanization accelerator, CBS (CZ) has demonstrated its excellent performance especially in the application of SBR rubber. This article will delve into the versatility of CBS (CZ) accelerator and its significant advantages in anti-burn performance and production efficiency.

CBS (CZ) accelerator has excellent vulcanization acceleration effect, and its unique chemical structure makes it excellent in improving the durability and anti-skid performance of SBR rubber. In addition, CBS (CZ) accelerator can effectively reduce gas release during the vulcanization process, thereby improving safety and environmental friendliness in production.

When applied to SBR rubber, CBS (CZ) accelerator significantly improves the anti-burn performance of the product. By optimizing the formula and adjusting the vulcanization conditions, the fire resistance of SBR rubber can be effectively enhanced to meet the safety requirements in industrial applications. This advantage is particularly important in fields such as transportation and large machinery and equipment, ensuring the safety of the operation process.

The use of CBS (CZ) accelerator not only improves the overall quality of SBR rubber, but also effectively shortens the production cycle. Its efficient vulcanization promotion effect enables rapid molding of rubber products and achieves higher production efficiency. This feature allows manufacturers to respond promptly and maintain a competitive advantage when facing market demands.

In summary, CBS (CZ) accelerator has demonstrated excellent performance in SBR rubber, especially in terms of anti-burn performance and production efficiency. For manufacturers pursuing high-quality rubber products, choosing CBS (CZ) accelerator is undoubtedly an important strategic decision. We look forward to seeing its outstanding performance in more application fields in the future.