In the production and application of rubber seals, durability is one of the important indicators to evaluate their quality. With the advancement of technology, many new materials and processing techniques have emerged. Among them, MBT(M) technology has attracted much attention due to its excellent performance.

MBT(M) technology is the latest technology developed specifically to improve the performance of rubber materials. It significantly improves the durability of rubber seals by optimizing the material formula and improving the processing technology. This technology has been successfully used in multiple industries and has demonstrated good performance.

This experimental analysis used standard testing methods to evaluate the impact of MBT(M) technology on the durability of rubber seals under various environmental conditions. During the experiment, we compared the performance of traditional rubber seals and seals produced with MBT(M) technology in multiple durability tests.

Experimental results show that MBT(M) technology significantly improves the durability of rubber seals. In environments such as high temperature, low temperature and chemical corrosion, seals using MBT(M) technology show excellent anti-aging and anti-fatigue properties, and their service life is significantly extended. This result provides an important reference for professionals in the industry.

To sum up, MBT(M) technology has injected new vitality into the production and application of rubber seals. Through this experimental analysis, I hope to provide useful insights to my peers and inspire more people in the industry to explore the application of new technologies in product development.

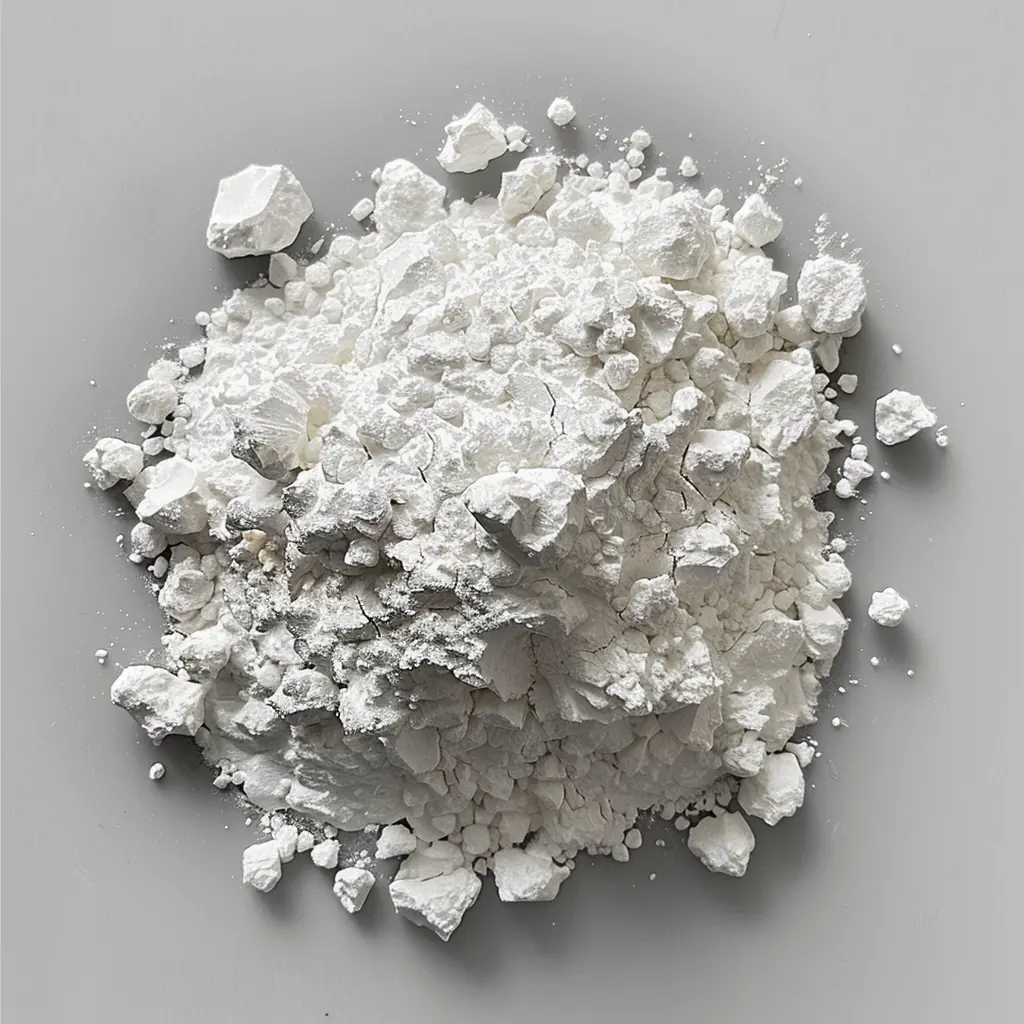

For more information, please see the images below: