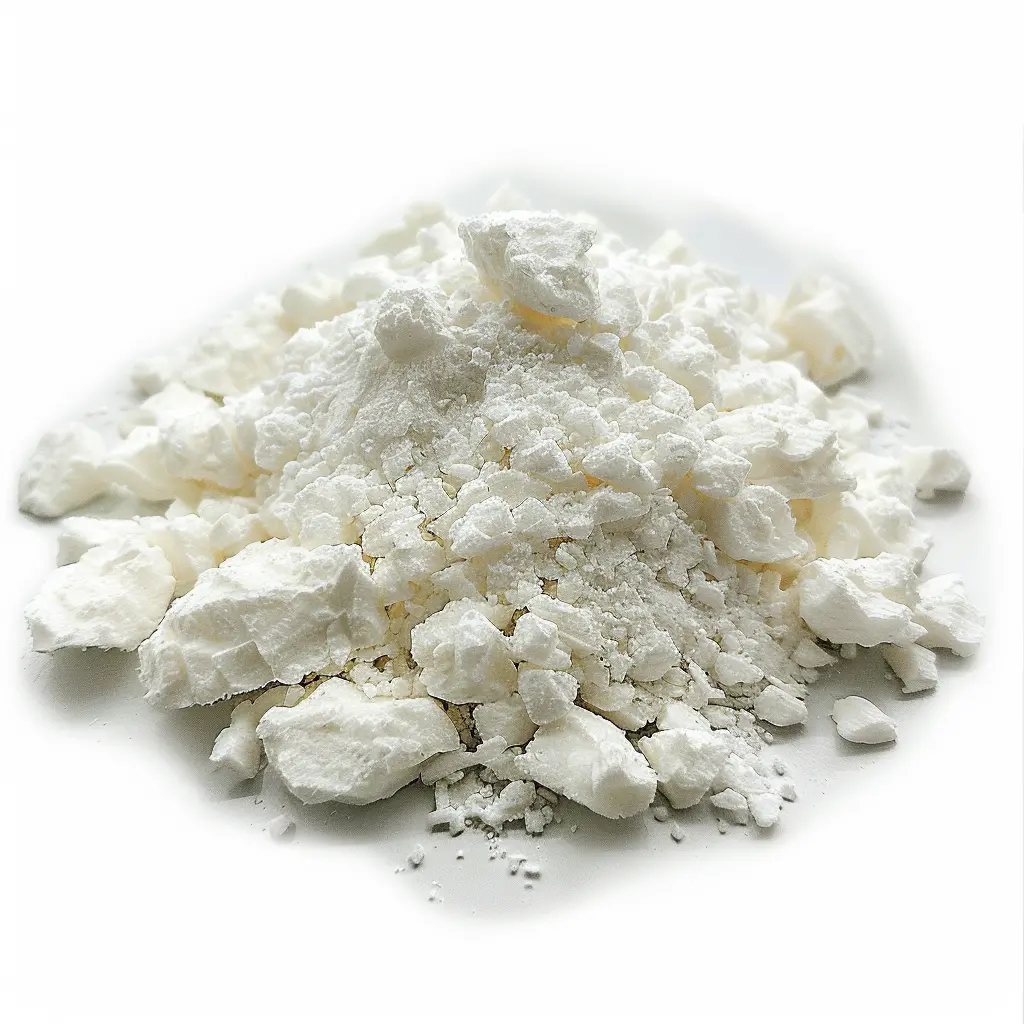

The sulfur vulcanization accelerator DCBS(DZ) is highly regarded in the rubber manufacturing industry for its remarkable properties and versatile applications. This article delves into its technical features, commercial applicability, and advantages in the production of various rubber products.

DCBS(DZ) offers superior performance in enhancing the curing process of rubber. Its unique chemical structure allows for efficient cross-linking of rubber polymers, resulting in improved mechanical properties. Studies show that products featuring DCBS(DZ) have significantly better resilience and durability.

DCBS(DZ) is widely utilized in the production of radial tires, shock absorbers, and rubber belts. Its ability to enhance performance makes it a preferred choice among manufacturers aiming for high-quality and long-lasting products.

The use of DCBS(DZ) leads to enhanced product performance due to its efficient curing capability. It is environmentally friendly and meets various regulatory standards, contributing to sustainable manufacturing practices.

In summary, DCBS(DZ) stands out as a leading sulfur vulcanization accelerator, offering technical features and commercial applications that ensure the production of high-quality rubber products. Its adaptability and efficiency solidify its role as an essential component in the rubber manufacturing industry.