In the plastics industry, plasticizers are an indispensable additive, and their main function is to improve the processing and performance of plastics. Among the many plasticizers, thermal stability is a key parameter that directly affects the quality and service life of the final product. This article will share how to choose high-quality plasticizers to improve thermal stability and product performance.

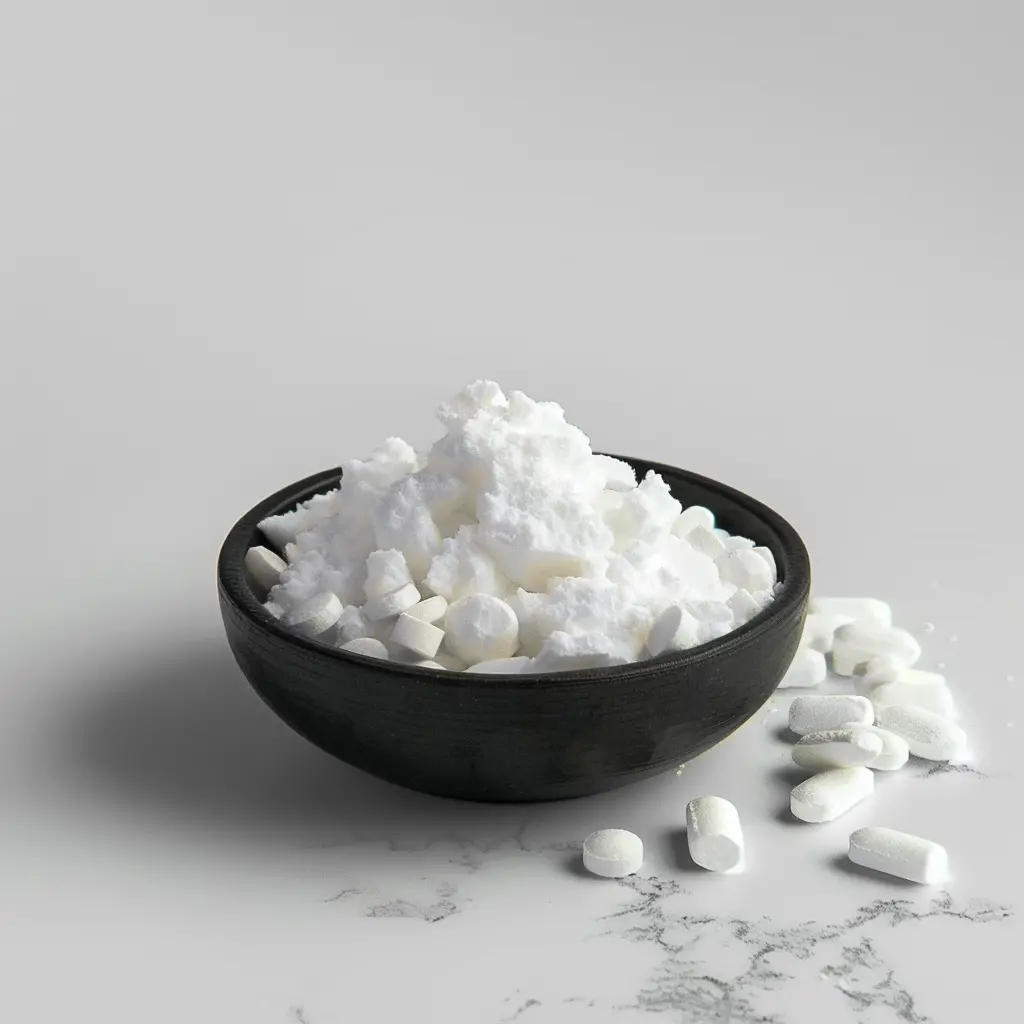

There are many types of plasticizers on the market, the most common ones include phthalates, fatty acid esters, etc. Different types of plasticizers have different physical, chemical properties and thermal stability. Choosing a suitable plasticizer requires comprehensive consideration of various indicators.

Thermal stability is an important indicator for plasticizers to maintain their performance without degradation in high temperature environments. High-quality plasticizers should have high thermal stability to ensure that the product can maintain good physical and mechanical properties during processing and use.

When choosing a plasticizer, you should pay attention to the following aspects:

Comprehensive consideration of plasticizer types, thermal stability and performance evaluation can help you make wise choices to improve the use of plastic materials. In the process of selecting plasticizers, we hope that you can pay attention to its thermal stability to improve the overall performance of the product and provide strong support for your business development.