Quality control in the rubber industry is crucial and is directly related to product performance and market competitiveness. The following analyzes the four main factors that affect rubber quality:

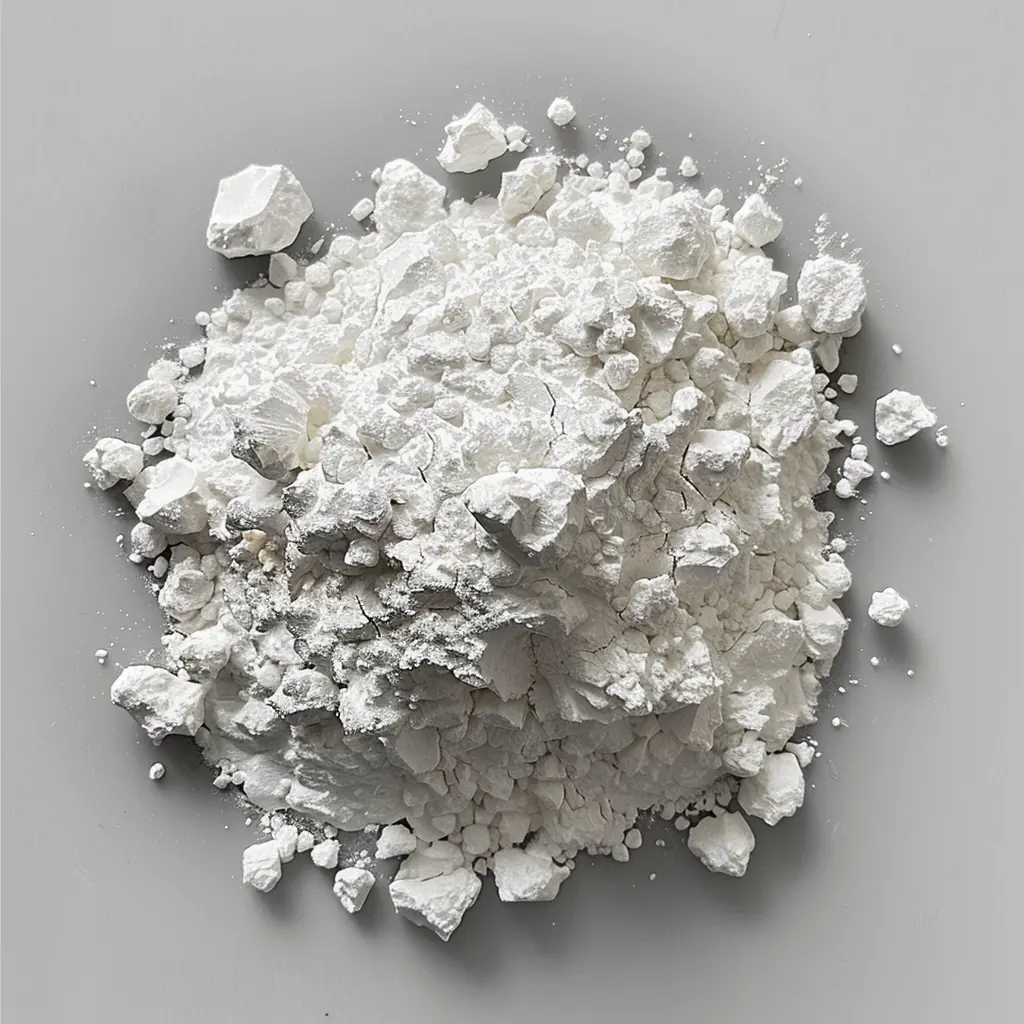

The selection of high-quality natural and synthetic rubber is the basis for ensuring product performance and durability. When selecting raw materials, attention should be paid to their physical and chemical properties.

Strict control of production parameters such as temperature, pressure and mixing time has an important impact on the uniformity and physical properties of rubber. For example, appropriate temperature and mixing time can significantly improve various indicators of rubber.

The cleanliness and humidity of the production environment will affect rubber quality in subtle ways. Maintaining a good production environment is an effective way to improve product quality.

Post-processing such as vulcanization is an important step in significantly improving rubber performance. Reasonable processing procedures can ensure that the final product meets the expected performance indicators.

Through in-depth analysis of these factors, companies can better formulate corresponding quality control measures, thereby improving the overall quality and market competitiveness of rubber products.

Through the above analysis, we can provide effective basis for improving the quality of rubber products and ensure that enterprises achieve sustained growth in the fiercely competitive market.